Complete Guide to Valve Leakage Classes (Class I–VI)

05.01.2025 | Valve Standards & Specifications

Understand leakage class ratings, standards, and real-world applications

Overview

Valve leakage classes define how much fluid or gas a valve is allowed to leak when fully closed. These standards are critical in selecting control and isolation valves for applications where tight shut-off or minimal leakage is essential.

In this guide, you'll learn:

- What Are Valve Leakage Classes?

- Valve Leakage Class Chart (Quick Reference)

- Understanding Each Leakage Class (I–VI)

- How Are Leakage Classes Tested?

- Real-World Applications by Leakage Class

- Related Resources

- Conclusion: What Class Do You Need?

What Are Valve Leakage Classes?

Valve leakage class is a standardized rating that defines the maximum allowable internal leakage through a valve when it’s fully closed.

These ratings range from Class I (least strict) to Class VI (most stringent). They're governed by standards such as:

- ANSI/FCI 70-2

- IEC 60534-4

- API 598 (for testing)

Valve Leakage Class Chart (Quick Reference)

| Leakage Class | Maximum Allowable Leakage | Test Medium |

|---|---|---|

| Class I | No test required | No test required |

| Class II | 0.5% of rated capacity | Air or water at 50-125°F (10-52°C) |

| Class III | 0.1% of rated capacity | Air or water at 50-125°F (10-52°C) |

| Class IV | 0.01% of rated capacity | Air or water at 50-125°F(10-52°C) |

| Class V | 0.0005 ml/min/in of port diameter per psi differential | Water at 50-125°F(10-52°C) |

| Class VI | 0.15 to 0.3 ml/min (air/water) | Air or nitrogen at 50-125°F(10-52°C) |

Understanding Each Leakage Class

Class I – No Leakage Test Required

Assumes inherent seat tightness. Common in utility-grade valves.

Class II – Low Leakage

Slight leakage allowed under test conditions. Typically metal-to-metal seated valves.

Class III – Moderate Leakage

Tighter than Class II, but not bubble-tight. Used in non-critical process controls.

Class IV – Tight Shut-off for Process Control

Often called “industrial tight shutoff.” Requires metal-to-metal sealing. Common in chemical plants and refineries.

Class V – Very Low Leakage

Used in clean service, high-pressure applications. Fluids: water, air, steam at 100 psi. Tested with water, not air.

Class VI – Bubble-Tight Shutoff

Tested with air or nitrogen. Common in soft-seated valves (e.g., PTFE, TFM 1600). Required in gas service, pharma, and food-grade systems.

How Are Leakage Classes Tested?

Leakage class testing is typically done per ANSI/FCI 70-2 or IEC 60534-4.

Common Test Parameters:

- Test media: water, air, or nitrogen

- Test pressure: ~3.5 bar (for Class V)

- Test duration: 60–120 seconds

- Temperature: ambient

Note: For valves like API 608 ball valves, testing may also follow API 598.

Real-World Applications by Leakage Class

| Industry | Recommended Class |

|---|---|

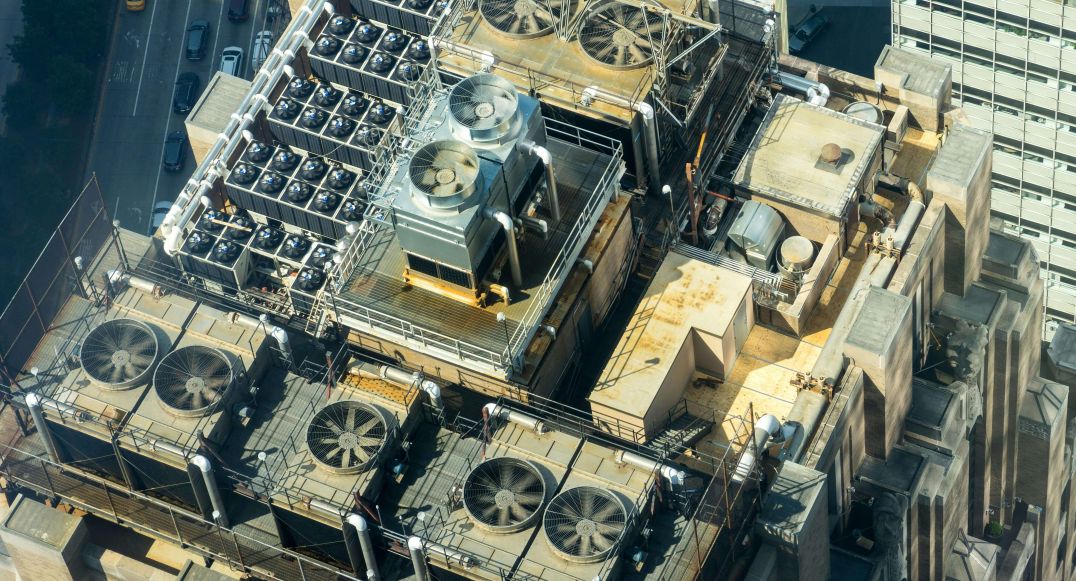

| HVAC & Water Systems | Class II or III |

| Oil & Gas (Upstream) | Class IV–V |

| Chemical Processing | Class IV–VI |

| Food & Beverage / Pharma | Class VI |

| Steam Isolation | Class III–IV |

Related Resources

Conclusion: What Class Do You Need?

For most industrial applications, Class IV or V will be sufficient. But for pharmaceutical, food-grade, or hazardous gas systems, only Class VI bubble-tight shut-off is acceptable.

Need help selecting the right valve or testing method?

Contact SVF valve experts or explore our full range of valves →