Fire Safe Valves: A Critical Component for Safety and Reliability in Industrial Applications

10.24.2024 | Industry News

Fire Safe Valves: A Critical Component for Safety and Reliability in Industrial Applications

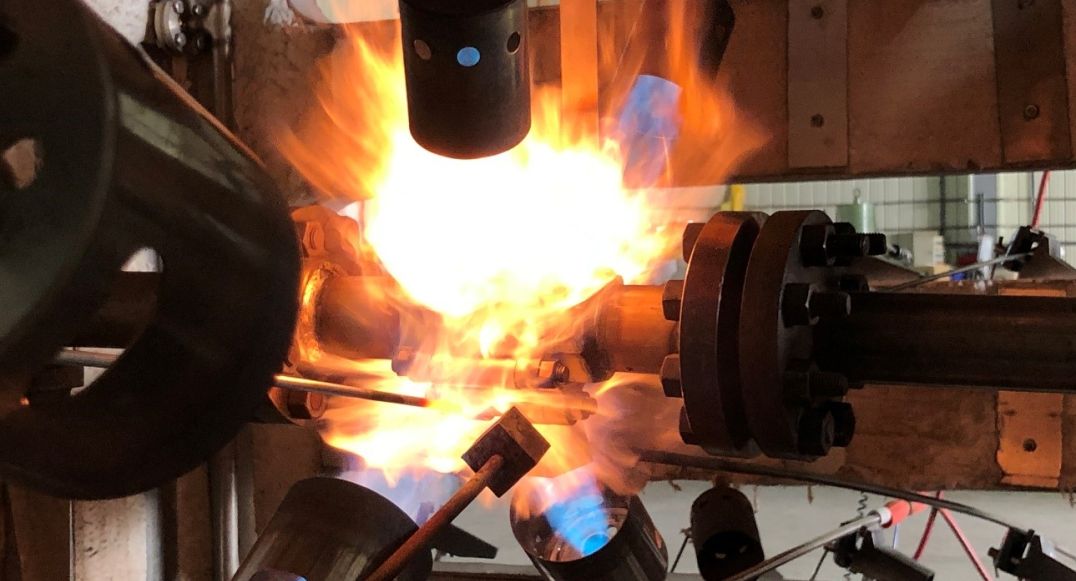

When it comes to industrial applications, safety is a top priority. Certain industries like oil and gas, chemical processing, pharmaceutical, cosmetics and energy production, come with a risk of fire or explosion. This is where fire safe valves play a crucial role. These valves are designed to maintain their integrity and functionality even when exposed to extreme heat, providing a vital safety mechanism in the event of a fire. In this blog post, we’ll explore the key features and benefits of fire safe valves and why they are an essential component in safeguarding your operations.

Key Features of Fire Safe Valves

1. High-Temperature Resistance

Fire safe valves are built to withstand extreme heat. They use materials and construction techniques that prevent valve components from melting or distorting when exposed to temperatures typically encountered in fires. Common materials include stainless steel and carbon steel, which are highly resistant to heat and corrosion.

2. Secondary Metal Sealing Mechanism

A critical feature of fire safe valves is the inclusion of a secondary metal-to-metal seal. If the primary soft seat material (such as PTFE or other plastics) is compromised during a fire, the valve still has a secondary seal made of grafoil, which ensures continued containment of the process fluid.

3. Certified Testing Compliance

Fire safe valves undergo rigorous testing under established standards like API 607 (for soft-seated quarter-turn valves) and API 6FA (for gate, globe, and check valves). These standards simulate the extreme conditions of a fire and certify that valves meet the necessary requirements for fire safety.

4. Full Bore and Reduced Bore Options

Fire safe valves are available in both full bore and reduced bore configurations, providing flexibility for various applications. Full bore valves ensure minimal flow resistance, while reduced bore valves can be used where smaller flow rates are required without compromising fire safety.

Benefits of Fire Safe Valves

1. Enhanced Safety

The most significant benefit of fire safe valves is the protection they offer during fire-related emergencies. By preventing flammable liquids or gases from leaking and fueling the fire, these valves contribute to safeguarding personnel, equipment, and the environment.

2. Minimization of Downtime

In the event of a fire, valves that fail can lead to significant downtime and costly repairs. Fire safe valves are designed to continue functioning even in extreme conditions, reducing the likelihood of catastrophic failure, and minimizing production losses.

3. Compliance with Industry Standards

Fire safe valves help industrial operations remain compliant with safety regulations and industry standards. By using certified fire safe valves, companies demonstrate their commitment to maintaining a safe and reliable operation, which can also reduce insurance premiums and regulatory fines.

4. Cost-Effective Long-Term Investment

While fire safe valves may have a higher upfront cost compared to standard valves, their long-term reliability and safety benefits make them a cost-effective choice. They reduce the risk of expensive incidents and provide peace of mind that your facility is well-protected against fire hazards.

5. Wide Range of Applications

Fire safe valves are suitable for a variety of applications, including refineries, petrochemical plants, offshore drilling platforms, and chemical processing facilities. Their ability to handle high-pressure and high-temperature conditions makes them a versatile and essential component in fire-prone environments.

Fire safe valves are a critical safety feature in industrial systems where flammable materials are handled. Their ability to function reliably under fire conditions not only protects equipment and personnel but also ensures compliance with safety regulations. By investing in high-quality, certified fire safe valves, companies can significantly enhance their fire protection measures and minimize the risks associated with fire-related incidents.

SVF Flow Controls is committed to providing top-tier fire safe valve solutions that meet the highest safety standards. Check out our collection of fire safe valves, SB7X, FB9, B41D, B42D and B43D Ball Valves--all engineered to be a true process piping component to specifically meet the demanding processes found in the Pharmaceutical and Food & Beverage industries. Contact us today to learn more.